Turning End-of-Life Wind Blades into Usable Material

- The Material Challenge

- Why Size Reduction Is Essential

- Hammer Mill Advantages for Composite Processing

- From Blade Waste to Construction Materials

- Key Takeaways — Wind Turbine Blade Recycling

- Let's Connect!

- A Practical Solution for Recycling Wind Turbine Blades

- Schutte Hammermill Solutions for Turbine Blade Recycling

- Frequently Asked Questions

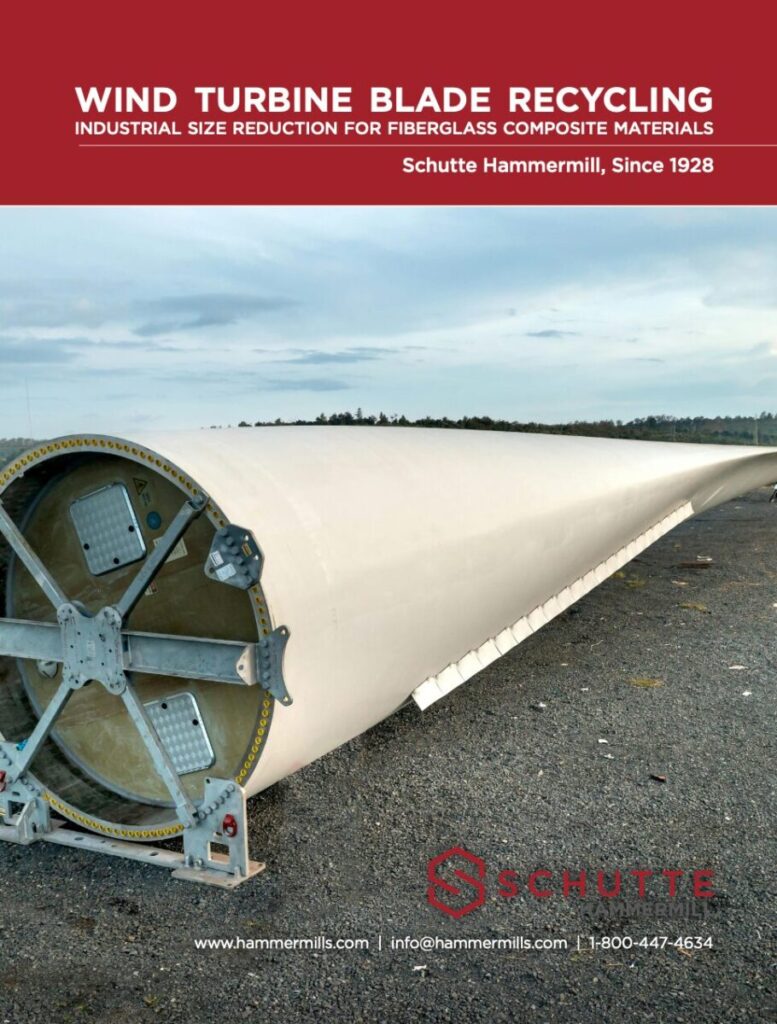

Wind energy infrastructure is expanding rapidly, and with that growth comes a new industrial challenge: processing end-of-life turbine blades. Built from high-strength fiberglass and composite materials, these massive structures were engineered for durability, not disposal.

As landfill restrictions tighten and recycling initiatives grow, processors are seeking practical solutions to convert bulky composite blades into reusable material streams. Mechanical size reduction is emerging as the critical first step in that process.

Industrial hammer milling enables efficient breakdown of rigid composite structures into consistent fractions suitable for downstream applications including alternative concrete, construction fillers, and engineered materials.

Read More: The Growing Challenge of Wind Turbine Blade Recycling, and Why Processing Matters

The Material Challenge

Wind turbine blades present unique processing demands:

- Dense fiberglass composite construction

- Abrasive material characteristics

- Large, irregular feedstock

- Layered structural design

These properties require robust equipment capable of delivering high-impact fracture energy while maintaining controlled particle sizing.

Why Size Reduction Is Essential

Before composite blade material can be reused, it must be processed into a manageable, uniform form. Effective size reduction:

- Reduces volume for transport and storage

- Produces consistent particle sizing

- Improves downstream blending performance

- Enables integration into construction materials

Hammer milling transforms rigid blade sections into a predictable feedstock that supports emerging recycling and reuse pathways.

Hammer Mill Advantages for Composite Processing

Heavy-duty hammer mills are particularly suited for fiberglass composite reduction because they provide:

- High-energy impact fragmentation

- Adjustable screen control for target sizing

- Continuous throughput capability

- Wear-resistant components for abrasive materials

Systems can be configured to balance throughput, durability, and particle uniformity, critical when processing challenging composite feedstock.

From Blade Waste to Construction Materials

Once reduced, composite fractions can serve as reinforcement fibers or fillers in alternative concrete and building materials helping divert large-scale waste while supporting innovative material recovery efforts.

Mechanical size reduction bridges dismantling operations and material reuse, making blade recycling scalable and economically viable.

Read More: Grinding Wind Turbine Blades: Preparing Composite Materials for Construction Reuse

Key Takeaways — Wind Turbine Blade Recycling

- Wind turbine blades are constructed from durable fiberglass composites that require industrial-grade processing to recycle effectively

- Mechanical size reduction is the critical first step that enables downstream reuse in construction and engineered materials

- Hammer milling delivers the impact energy needed to fracture rigid composite structures into consistent, usable fractions

- Proper equipment configuration supports controlled particle sizing, throughput, and wear management

- Recycling blade material can reduce landfill burden while unlocking new material value streams

Let’s Connect!

A Practical Solution for Recycling Wind Turbine Blades

Mechanical size reduction is emerging as the foundation of scalable wind blade recycling. By transforming rigid composite structures into controlled particle fractions, processors can unlock new pathways for reuse in construction and engineered materials. Download our Wind Turbine Application Sheet to learn more

Schutte Hammermill Solutions for Turbine Blade Recycling

RAS Two-Stage Hammer Mill: Heavy-Duty Composite Reduction

- Designed for high-impact grinding of dense, rigid composite materials

- Robust rotor assembly delivers consistent fracture of layered fiberglass structures

- Heavy-duty housing and wear components built for abrasive feedstock

- Adjustable screen configuration allows controlled particle sizing

- Continuous-duty design supports industrial throughput requirements

WA Series Hammer Mills: Versatile Industrial Grinding

- Proven performance in abrasive and irregular material processing

- Flexible screen options for application-specific output sizing

- Durable construction engineered for long-term wear resistance

- Smooth material flow supports consistent feed handling

- Well suited for integration into staged blade recycling systems

44 Series Full Circle Hammer Mill: Controlled Size Reduction

- Efficient impact grinding for pre-sized composite fractions

- Precise particle sizing control for downstream blending applications

- Rugged design capable of handling fiberglass materials

- Ideal for secondary processing or finishing passes

- Supports repeatable output consistency for construction reuse

Application Support & Equipment Configuration

Every processing application is unique. Factors such as feedstock preparation, desired particle size, throughput goals, and wear considerations influence equipment selection and system design.

Frequently Asked Questions

Yes — while turbine blades were not originally designed with recycling in mind, growing regulatory pressure and landfill restrictions are driving new recovery pathways. Mechanical size reduction allows composite blade material to be converted into usable fractions for construction applications, engineered fillers, and alternative material blends. Recycling viability depends heavily on proper preprocessing and downstream use.

Wind blades are dense fiberglass composites that cannot be directly incorporated into secondary products. Size reduction breaks down rigid structures into consistent particles that improve handling, blending, and material performance. Without this step, reuse applications are limited and difficult to scale.

Blade construction combines fiberglass reinforcement and resin layers designed for structural strength. This creates abrasive, irregular feedstock that resists conventional grinding. Equipment must be engineered to withstand wear while delivering sufficient impact energy to fracture composite layers efficiently.

Industrial hammer mills are well suited for rigid composite processing because they apply high-energy impact forces that fracture layered materials. Proper configuration, including rotor speed, hammer design, and screen sizing, allows operators to balance throughput, particle uniformity, and wear resistance when processing fiberglass composites.

Heavy-duty systems from Schutte Hammermill are designed for demanding size reduction applications and can be customized for abrasive composite feedstock.

Yes — mechanical size reduction systems are designed for continuous industrial operation. With proper system configuration, processors can achieve reliable throughput while maintaining consistent particle sizing and wear management.

The most active area of reuse is construction, where composite fractions can function as fillers or reinforcement in alternative concrete and engineered materials. Research and industrial innovation continue to expand potential end uses.

Every composite processing application is unique. Factors such as blade composition, desired particle size, throughput requirements, and wear expectations influence system design. Application testing and consultation help ensure equipment is properly configured for reliable performance.

Talk With a Size Reduction Specialist

If you are exploring wind blade recycling or composite material recovery, our team can help evaluate your application and recommend a processing solution.