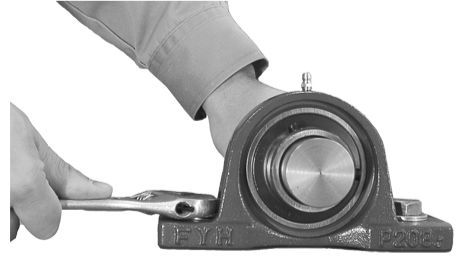

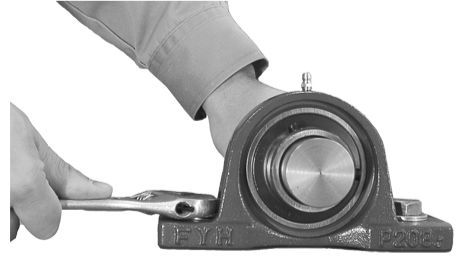

Note: Always replace bearings in pairs.

Note: Always replace bearings in pairs.

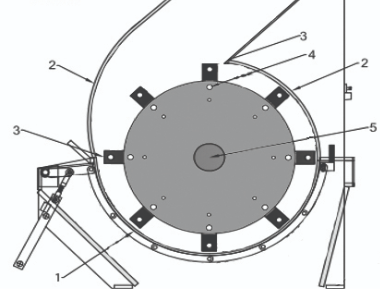

To prepare for replacement, contact us for a set of replacement hammers. Each row of hammers is wired into a specific order and balanced as a set at the factory. You must maintain the order of the hammers and this balance as you make changes. If you do not, the unbalanced hammers can cause excessive… Read more »

Machines that reduce the size of a material also erode the grinding elements. In general, the more abrasive the material you grind, the more quickly the wear parts in the interior will wear. To ensure efficient operation and longevity of your Hammer mill, it’s crucial to regularly inspect and maintain its wear parts. These components… Read more »

In the dynamic landscape of feed processing and biomass production, the cornerstone lies in efficient size reduction and pelleting. Schutte Hammermill recognizes the pivotal role these processes play in optimizing productivity and ensuring superior product quality. In this blog post, we delve into the significance of size reduction and pelleting solutions and explore how Schutte… Read more »

Any machine that has moving or rotating parts requires routine maintenance to ensure that it performs at optimal capacity. This is especially true of size reduction equipment which has grinding elements that will wear over time. Schutte Hammermill equipment is very ruggedly constructed and with proper routine maintenance will remain in service for many years… Read more »