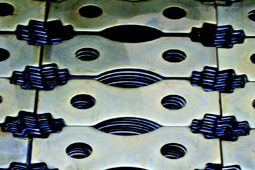

No costly downtime. For Cargill, finding the right grinder to meet their production schedule was a challenge. After many others failed to perform as promised, the Schutte-Buffalo Model 1590 delivered! Processing at a rate of 500,000 pounds per day and giving the customer the production rate and end product required, with no need to shut down production for daily… Read more »