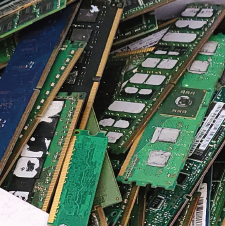

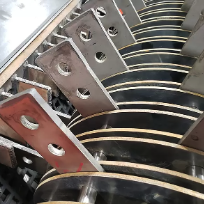

To ensure the continued efficiency and longevity of your size reduction equipment, periodic inspection and replacement of wear parts is of paramount importance. In this knowledge base article, we will delve into the importance of maintaining wear parts for your equipment. Maintaining Operational Efficiency One of the primary reasons for using replacement parts in size… Read more »