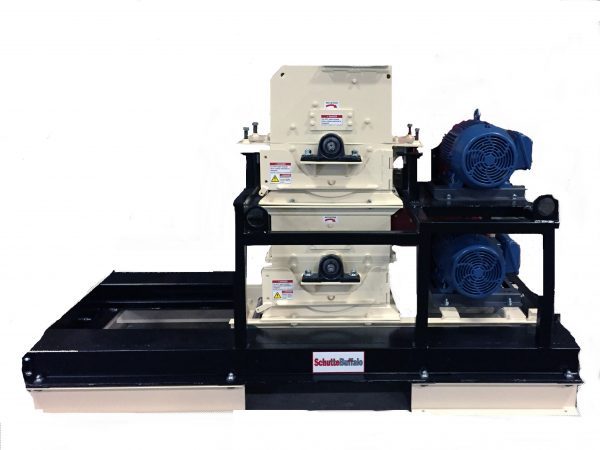

RA Series Dual Stage Hammer Mill

The RA Series Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to a ultra fine finished particle size.

The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the dual stage mill, than can be achieved in multiple passes through a single hammer mill.