Engineered systems for processing post-consumer carpet, separating reusable materials, and supporting compliance with evolving recycling regulations.

Carpet is one of the most challenging post-consumer waste streams to recycle. Made from layered composites of fibers, adhesives, and mineral-filled backing, used carpet has historically been landfilled due to its bulk, complexity, and processing difficulty.

Today, that’s changing. New state-level regulations, manufacturer recycled-content requirements, and rising disposal costs are driving increased demand for effective carpet recycling solutions. At the center of these solutions is size reduction—the critical first step that enables material separation, recovery, and reuse.

Schutte Hammermill provides proven size reduction systems engineered specifically to process used carpet and prepare it for downstream recycling and classification.

Why Carpet Recycling Is Gaining Momentum

Over the past several years, multiple U.S. states have introduced or expanded regulations aimed at reducing carpet waste and increasing recycled content in new carpet manufacturing. These initiatives are part of a broader push toward extended producer responsibility (EPR), shifting more end-of-life accountability to manufacturers and suppliers.

Key regulatory trends include:

- Minimum post-consumer recycled (PCR) content requirements in new carpet products

- Restrictions on certain backing materials and additives

- Increased diversion targets to reduce landfill disposal

While requirements vary by state, the direction is clear: carpet must be recyclable at scale. This shift is accelerating investment in processing technologies capable of handling post-consumer carpet efficiently and economically.

Read More: Why Carpet Recycling Is Gaining Momentum in the U.S.

The Role of Size Reduction in Carpet Recycling

Size reduction is the foundational step in carpet recycling. By breaking down bulky rolls, tiles, and slabs into smaller, manageable particles, size reduction enables:

- Liberation of fibers from mineral-filled backing systems

- Reduction of material volume for efficient handling and transport

- Preparation of material for downstream separation technologies

Without proper size reduction, carpet materials remain too entangled and inconsistent for effective recovery.

Read More: How Size Reduction Enables Carpet Recycling and Material Recovery

Removing Calcium Carbonate Backing for Material Recovery

Many carpet backing systems contain high levels of calcium carbonate filler. While essential for carpet performance, this mineral content complicates recycling by contaminating fiber streams.

Schutte Hammermill size reduction systems are engineered to:

- Break down backing systems effectively

- Release calcium carbonate from polymer fibers

- Produce material suitable for air classification and separation

This process allows recyclers to recover cleaner polymer fractions while isolating mineral-heavy fines into separate output streams.

Read More: Understanding Carpet Construction: Why Recycling Is So Challenging

Let’s Connect!

Schutte Hammermill Solutions for Carpet Recycling

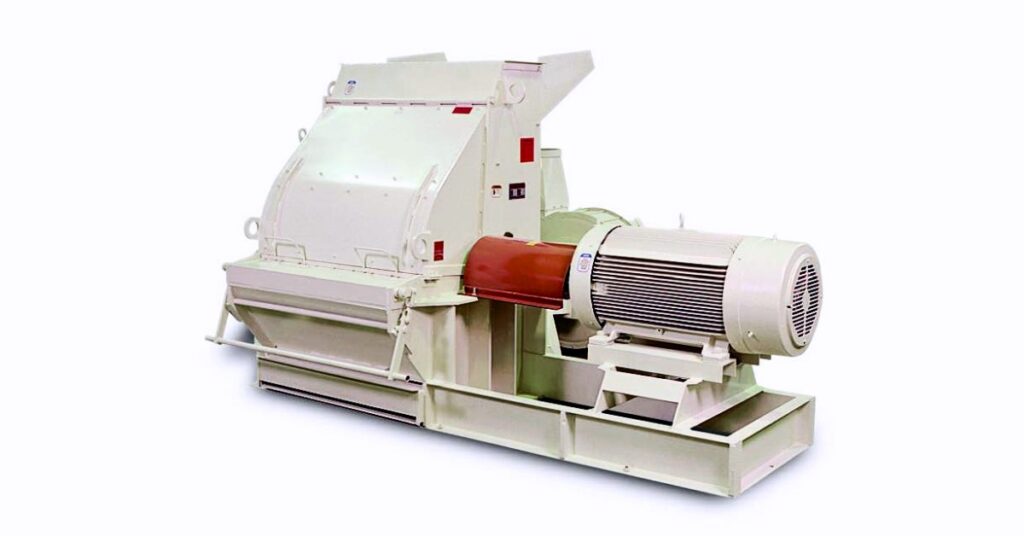

15 Series “Liberator” Hammer Mill

Designed for aggressive primary size reduction, the 15 Series Liberator excels at processing tough, composite materials such as post-consumer carpet.

Key advantages:

- Effective liberation of backing systems and fibers

- Fixed rotor design for consistent, high-impact processing

- Capable of handling rolled, folded, or slab carpet

WA Series Hammer Mills

The modified WA series is ideal for secondary size reduction or refinement following primary processing.

Key advantages:

- Controlled particle sizing

- Consistent output for downstream separation

- Adaptable configurations based on material and throughput goals

See It In Action!

Frequently Asked Questions

Carpet is made from multiple bonded materials, including fibers, adhesives, and mineral-filled backing, which must be separated for effective recycling.

Schutte Hammermill systems can process nylon, polyester, and olefin-based carpets, including broadloom carpet and carpet tile.

Yes. Proper size reduction liberates calcium carbonate from polymer fibers, allowing separation through air classification.

A complete system typically includes primary and secondary size reduction equipment and optional air classification for material separation.

Yes. Schutte Hammermill engineers and supplies complete size reduction and separation systems tailored to specific recycling goals.

A Practical Solution for Recycling Carpet

Looking to process post-consumer carpet more efficiently? Our Application Sheet outlines the key challenges, material considerations, and size reduction solutions involved in modern carpet recycling systems.