Why a hammer mill?

Hammer mills can be used to process a seemingly infinite list of materials. For spices it is the best tool for the job because of the operational flexibility, and the ability to control finished particle size. With the exception of high oil content spices such as nutmeg and mace (unless cryogenically frozen), the hammer mill is ideal for processing a wide variety of spices and dried herbs, such as : red pepper, white pepper, black pepper, coriander, cumin, cinnamon, oregano, thyme, cloves, and turmeric just to name a few…

One mill, many spices

The simplicity of the hammer mill makes it very adaptable to the varying characteristics of different spices. It is this versatility that makes the hammer mill the ideal choice for those processing more than one variety. Because the processing mechanism results in crushing by impact instead of compression, spices are ground to the exact desired particle size without significant heat increase that could cause loss of flavor or aroma.

Sizing

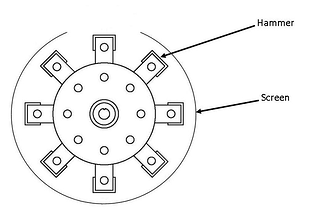

The importance of exact finished particle size cannot be overstated when grinding spices. The key component to a hammer mill processing the exact particle size is the perforated screen covering the mill’s discharge opening. Screen selection allows the processor to determine the largest allowable finished particle size. Material remains in the mill’s grinding chamber and continues to be pulverized until it is able to pass through the screen. Screens of varying sizes can be used interchangeably in the same mill. A 1/8” perforated screen will produce a coarser tea cut finished size. Whereas a 1/32” screen will produce a fine powder. The second component of particle size determination is the rotor speed. As the rotor spins, the hammers impact the material in the grinding chamber with great severity.

Generally speaking:

High rotor speed = increased number of severe hammer blows = finer particle size

Slower rotor speed = decreased number of softer hammer blows = coarser particle size

In addition, very hard materials such as cloves, ginger and turmeric will require a higher rotor speed to produce the same finished particle size as softer materials like white and black pepper. An optional variable frequency drive electrical control allows the operator to easily speed up or slow the rotor speed as needed for different applications.

Hammer mills in many styles and sizes

Finally, what size and style of hammer mill is best? This is determined by in-feed material characteristics and desired throughput rate. For softer, easier to process materials, a hammer mill with a nearly full circle screen is most suitable.

The 300 degree screen coverage allows for the greatest throughput at the lowest horsepower.

Fibrous herbs, and roots such as kava, cassava, yam, carrot and ginseng are best ground in a more traditional industrial hammer mill.

Fibrous herbs, and roots such as kava, cassava, yam, carrot and ginseng are best ground in a more traditional industrial hammer mill.

This style of hammer mill contains an internal ribbed breaker plate which is the first point of contact when material enters the grinding chamber.

Given its ribbed construction, the breaker plate has a wash-board effect, breaking, down the material, thus making the pulverizing action of the hammers more efficient while reducing wear on the screens.

Both the circular screen and industrial hammer mill models range in size from pilot scale to high production models.

The size of the mill and the recommended horsepower of the motor is dependent on the processor’s throughput goals.