Industry-Leading E-Scrap Recycling, Data Destruction & Urban Mining Solutions

Schutte Hammermill delivers industrial size reduction solutions for e scrap recycling, secure data destruction, and urban mining. Our hammer mills and shredders, including the DataKiller Pro, RAS, RA, and WA series, provide precise particle size control, high throughput, and durable construction. These systems maximize material recovery, securely destroy data storage devices, and reduce waste volume, helping businesses improve efficiency, safety, and profitability.

Efficient Data Security and Material Recovery

Enter your information below to download our Free eBook: Efficient E-Scrap Size Reduction – Preparing Materials for Recovery

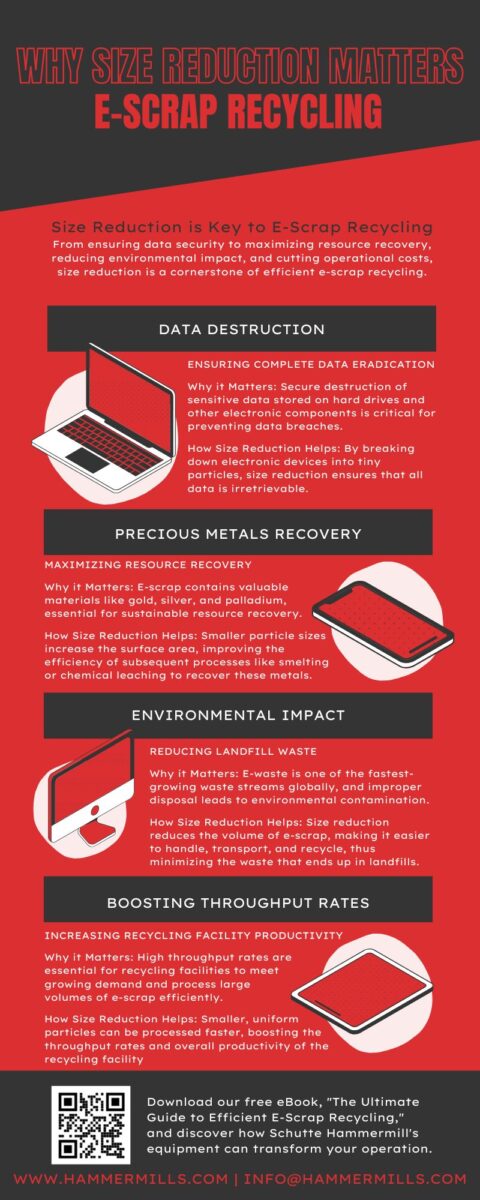

What is Size Reduction & How it Supports Your Goals

Electronic waste is the fastest-growing waste stream globally, driven by the rapid turnover of consumer electronics, IT infrastructure, and industrial devices. As organizations replace equipment more frequently, recyclers, ITAD providers, and manufacturers face increasing pressure to process growing volumes of complex electronic materials safely, efficiently, and securely.

At the core of effective e-scrap recycling, data destruction, and urban mining is size reduction — the controlled mechanical process of breaking large, bulky materials into smaller, more uniform particles. While often viewed as a simple mechanical step, size reduction plays a foundational role in the success of the entire downstream process.

Read More: The Importance of Size Reduction for Electronics Scrap Recycling

When e-scrap is properly reduced in size, it enables:

- Material Liberation & Resource Recovery

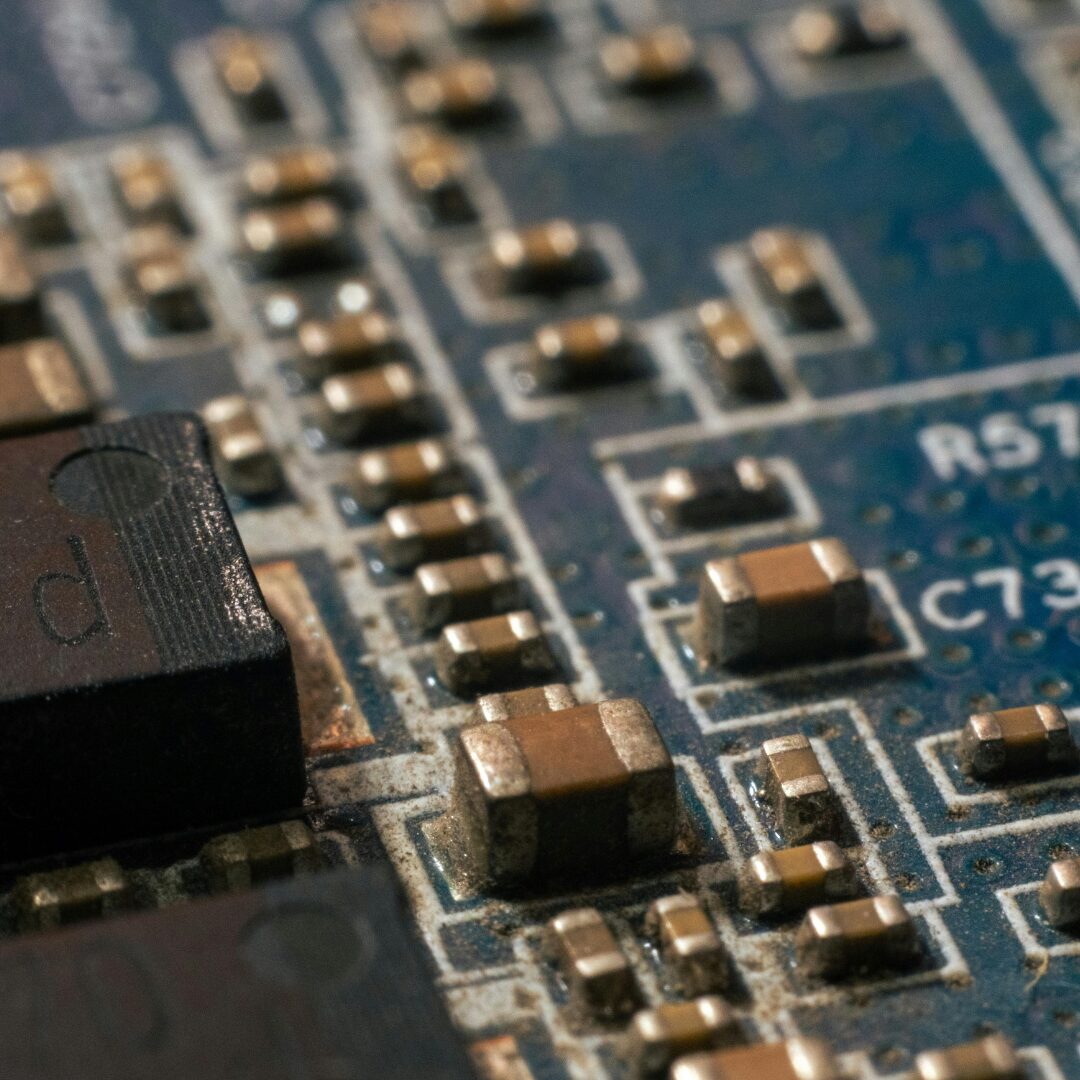

Electronic devices contain valuable metals such as gold, copper, aluminum, and rare earth elements that are tightly bound within plastics, circuit boards, and composite materials. Effective size reduction liberates these materials by separating metal components from non-metal substrates. Achieving a consistent, targeted particle size improves the performance of downstream separation technologies — including magnetic, eddy current, density, and optical sorting — resulting in higher recovery yields and increased material value.

Read More: e-Scrap Recycling and Urban Mining: How Size Reduction Enhances Resource Recovery - Secure Data Destruction

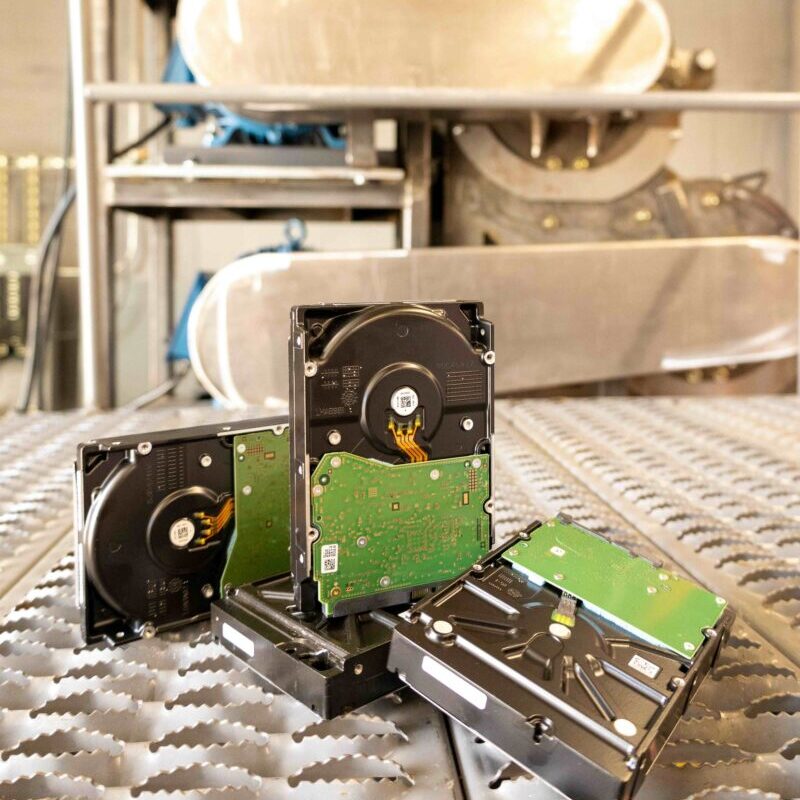

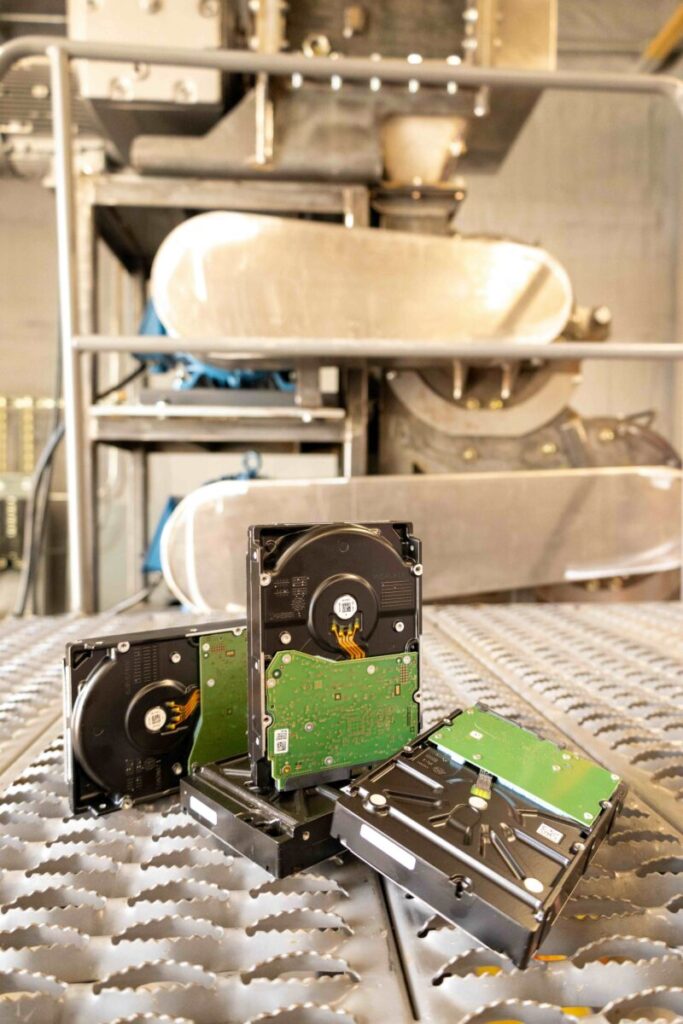

Physical size reduction is one of the most reliable methods for permanently destroying sensitive data stored on hard drives, solid-state drives, and other digital media. By mechanically breaking storage devices into fine, unrecognizable particles, size reduction ensures data cannot be reconstructed or recovered. This supports compliance with data protection standards and internal security requirements across IT asset disposition, data centers, and regulated industries.

Read More: The Role of Size Reduction in Secure Data Destruction - Volume Reduction & Operational Efficiency

Reducing e-scrap into smaller, uniform particles significantly decreases material volume, lowering costs for handling, storage, and transportation. Uniform sizing also improves material flow through automated processing lines, reduces equipment wear, and minimizes downtime caused by clogging or bridging.

Read More: Optimizing E-Scrap Recycling: Harnessing Hammer Mills for Efficient Size Reduction

In short, size reduction is not just a preprocessing step — it is a strategic enabler that directly impacts security, recovery efficiency, operational cost, and overall system performance across e-scrap recycling, data destruction, and urban mining operations.

Key Takeaway

Size reduction is the foundational process in e-scrap recycling, data destruction, and urban mining. By breaking electronic waste into smaller, uniform particles, size reduction enables secure data destruction, improves material liberation for precious metals recovery, and reduces volume for more efficient handling and transportation. Proper size reduction directly impacts downstream separation efficiency, compliance, and overall operational performance.

Let’s Connect!

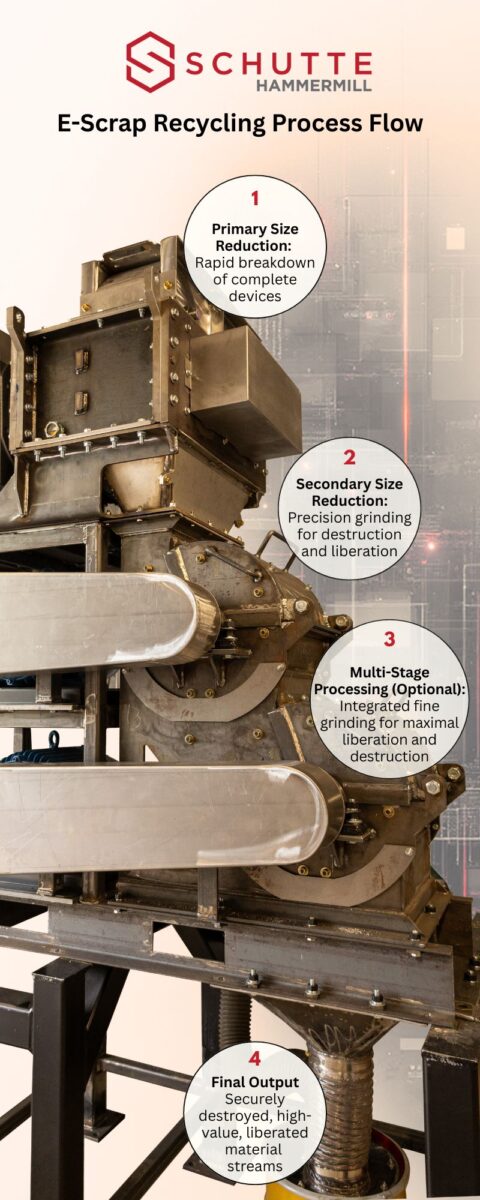

Schutte Hammermill Solutions for e-scrap processing

DataKiller Pro

Secure Data Destruction

The DataKiller Pro combines a dual-shaft shredder with a dual-stage hammer mill to achieve sub-2mm particle size in a single pass. It completely destroys data storage while liberating materials for downstream recovery.

Key Benefits:

- One-pass processing of HDDs, SSDs, and mixed electronics

- Industry-leading throughput

- Uniform particle size output

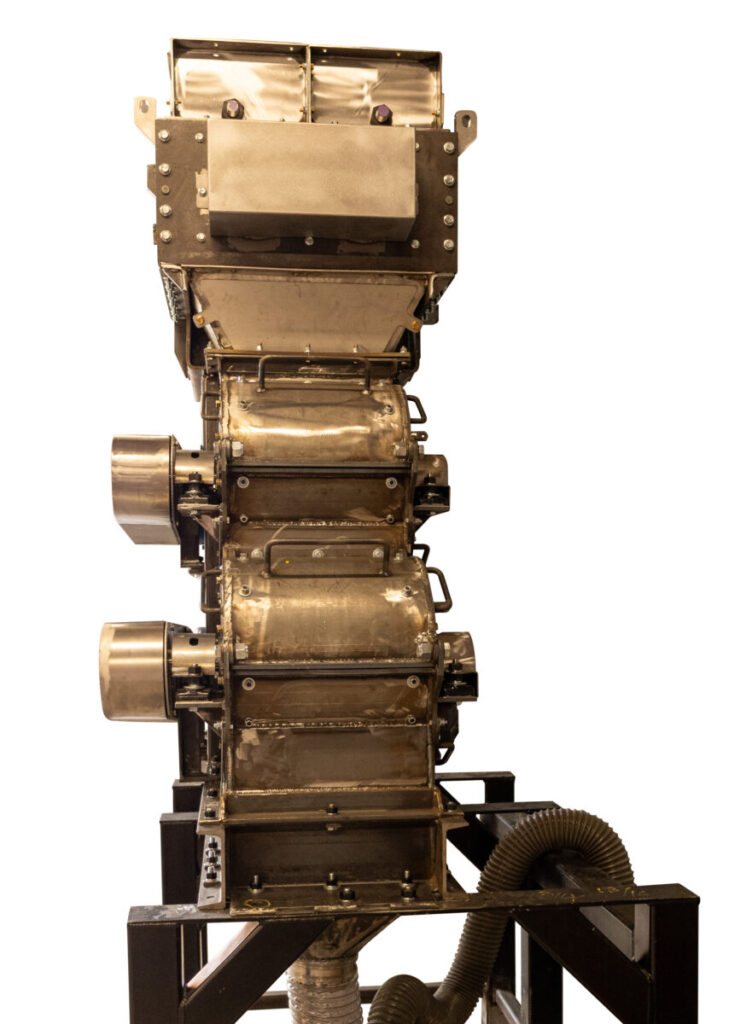

RAS Series

Precision Size Reduction

A Dual-stage hammer mills engineered for mixed e-scrap, providing uniform particle sizes to maximize metal recovery and material separation efficiency.

Key Benefits:

- High throughput for large-scale operations

- Dual-rotor precision grinding

- Customizable configurations for different feedstocks

RA Series

Dual-Stage Fine Grinding Mill

A high-performance dual-stage mill engineered for tough, bulky, and friable materials, the RA Series delivers consistent, ultra-fine particle sizes in a single pass — improving efficiency for separation and downstream processing.

Key Benefits:

- Ideal for demanding, large-scale operations

- Primary size reduction and ultra-fine grinding in one unit

- Tailored configurations for varied materials and processing goals

WA Series

Heavy duty for abrasive materials

Built for tough, abrasive electronics materials, the WA series handles challenging streams while protecting uptime and reducing maintenance requirements.

Key Benefits:

- Rugged construction for heavy-duty use

- Integration-ready for mixed-stream recycling lines

- Optimal particle size control for recovery and separation

See it in action!

FAQs: Frequently Asked Questions about e-scrap processing and recycling

- What are the best hammer mill options for e-scrap recycling?

Answer: Schutte Hammermill offers DataKiller Pro, RAS, RA, and WA series mills. The choice depends on feed material, target particle size, and throughput requirements.

- Can hammer mills ensure secure data destruction?

Answer: Yes. DataKiller Pro and dual-stage hammer mills physically destroy media to sub-2mm size, ensuring complete data erasure.

- How does size reduction improve metal recovery?

Answer: Smaller, uniform particle sizes allow separation equipment to efficiently recover metals from plastics, circuit boards, and other e-scrap components.

- What’s the difference between RAS and DataKiller Pro?

Answer: RAS is optimized for high-volume size reduction and metal liberation, while DataKiller Pro integrates shredding and dual-stage milling specifically for secure data destruction and downstream recovery.

- How do I choose the right particle size?

Answer: The ideal particle size depends on your recovery process and regulatory requirements. Schutte engineers can recommend configurations to achieve the desired size consistently.

Ready to dive deeper?

Check out these recent articles for even more information about e-scrap processing, and how Schutte Hammermill can help your process!

Efficient Data Security and Material Recovery

Enter your information below to download our Free eBook: Efficient E-Scrap Size Reduction – Preparing Materials for Recovery