For several decades, Schutte Hammermill has established a prominent presence in rendering facilities across the U.S. and Canada, with numerous successful installations. In each instance, their mills and grinders have demonstrated a clear superiority over industry standards in the processing of meat and bone for hi-pro meat meal and low-pro bone meal production. The track record of Schutte Hammermill's equipment in rendering applications speaks to its reliability, efficiency, and ability to consistently outperform industry benchmarks. This success has solidified Schutte Hammermill's reputation as a trusted provider of mills and grinders in the rendering sector, offering solutions that not only meet but exceed the stringent demands of meat and bone processing for the production of high-quality meals.

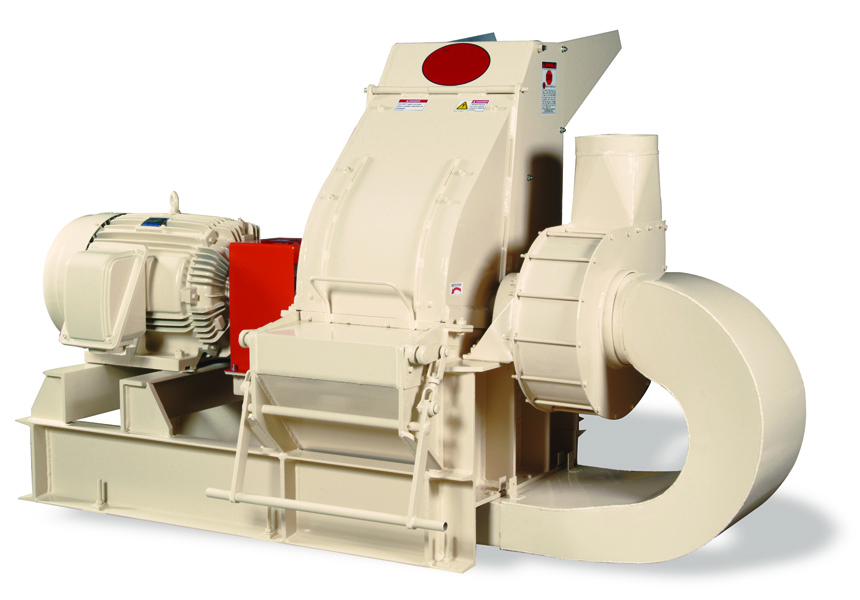

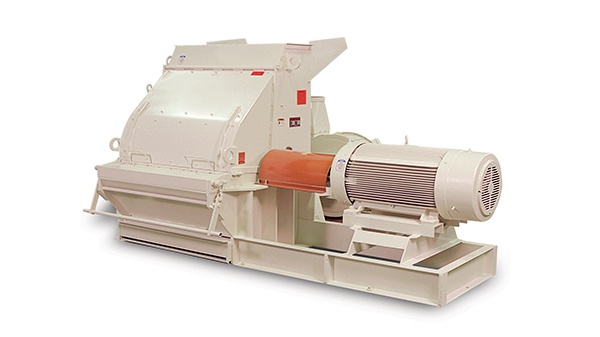

Equipment for Rendering

Reference Materials

Processed Materials

Meat Meal and Bone Meal