Молотковые дробилки незаменимы во многих отраслях, что делает их запасные части ценными для наличия, когда эти машины требуют ремонта.

Молотковые дробилки незаменимы во многих отраслях, что делает их запасные части ценными для наличия, когда эти машины требуют ремонта.

В любой промышленной среде, максимизация эффективности является основой прибыльности и успеха. Для компаний, которые используют молотковые дробилки и другое оборудование для измельчения, одним из ключевых факторов, влияющих на эффективность, является состояние изнашиваемых деталей. В Schutte Hammermill, мы понимаем, насколько важны заменяемые изнашиваемые детали для поддержания максимальной производительности… Подробнее »

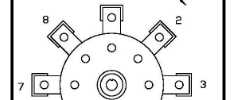

Стандартные молотки, используемые в наших мельницах, — это двусторонние оборотные типы, с четырьмя износными краями. Когда курки тупят настолько, что машина неэффективно шлифует или когда курки хорошо округлены, поверните молотки, чтобы новая острая кромка пошла в эксплуатацию. Один ряд молотков должен… Подробнее »

ЧАСТОТА ДЕЙСТВИЯ ДЕТАЛЕЙ Болты Осматривать Затянуть Ежедневные защитные Проверять ежедневные ремни Проверять ежедневные магниты Проверять ежедневные молотки Проверять еженедельно Вращать Кромка удара изношена. Заменить всё 4 кромки изношены. Экранировать или осматривать решётку еженедельно Заменить чрезмерно износные подшипники Проверять еженедельную заправку по мере необходимости Стержни молотка Проверять каждый раз при вращении молотков Заменить – Когда… Подробнее »

Машины, уменьшающие размер материала, также изнашивают элементы измельчения. В целом, чем более абразивен материал, который вы измельчаете, тем быстрее изнашиваются внутренние детали. Чтобы обеспечить эффективную работу и долгий срок службы вашей мельницы, it’s crucial to regularly inspect and replace its wear parts. These components include hammers, стержни, экраны,… Подробнее »