No cenário tecnológico em rápida evolução de hoje, a proliferação de dispositivos eletrónicos levou a um aumento correspondente de resíduos eletrónicos, ou e-lixo. Com uma estimativa de 53.6 milhões de toneladas métricas de resíduos eletrónicos gerados globalmente em 2019 somente, a necessidade de soluções eficazes de reciclagem nunca foi tão crítica. No centro do processo de reciclagem de e-lixo está a redução de tamanho, um passo fundamental que prepara os resíduos eletrónicos para o processamento subsequente. Neste artigo, exploramos a importância da redução de tamanho na reciclagem de e-lixo e examinamos o papel dos moinhos de martelos na obtenção de eficiência ótima.

Compreender a Importância da Redução de Tamanho

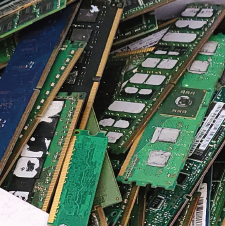

E-lixo, composto por eletrónicos obsoletos que vão de smartphones a computadores, contém materiais valiosos como metais preciosos, plásticos, e elementos de terras raras. No entanto, the efficient recovery of these resources is contingent upon effectively breaking down e-scrap into smaller, manageable pieces. Size reduction plays a pivotal role in enhancing the accessibility of these materials for subsequent separation and recovery processes.

Challenges in E-Scrap Size Reduction

E-scrap presents unique challenges in size reduction due to its diverse composition, which includes a mix of metals, plásticos, vidro, and other materials. Além disso, electronic devices come in various shapes and sizes, necessitating flexible and robust size reduction solutions capable of handling different types of e-scrap efficiently. Achieving the desired particle size distribution while minimizing energy consumption and equipment wear poses additional challenges in the e-scrap recycling process.

The Role of Hammer Mills in E-Scrap Recycling

Hammer mills have emerged as indispensable tools in e-scrap recycling, offering versatile and efficient size reduction capabilities. These machines utilize high-speed rotating hammers to pulverize materials, effectively reducing them to the desired particle size range. Hammer mills excel in processing a wide range of e-scrap materials, including circuit boards, unidades de disco rígido, and electronic components, thanks to their adjustable settings and rugged construction.

Advantages of Hammer Mills for E-Scrap Recycling

1. Versatilidade: Hammer mills can accommodate various types of e-scrap materials, enabling operators to process diverse feedstocks with ease.

2. High Efficiency The high-speed impact of hammers ensures rapid and effective size reduction, maximizing throughput while minimizing processing time.

3. Customizability Hammer mills offer adjustable settings to tailor particle size distribution according to specific requirements, optimizing resource recovery and downstream processing efficiency.

4. Construção Robusta: Designed to withstand the rigors of continuous operation, hammer mills boast rugged construction and durable components, minimizing downtime and maintenance costs.

Conclusão

Size reduction lies at the heart of e-scrap recycling, facilitating the recovery of valuable materials from obsolete electronics. Hammer mills stand out as indispensable tools in this endeavor, offering unparalleled versatility, eficiência, and reliability. As the demand for sustainable recycling solutions continues to grow, the role of hammer mills in e-scrap processing remains integral, driving innovation and maximizing resource recovery in the quest for a greener, mais sustentável.

Na Schutte Hammermill, Estamos comprometidos em fornecer soluções inovadoras de redução de tamanho, adaptadas aos desafios únicos da reciclagem de sucata eletrónica. Contacte-nos hoje para saber mais sobre a nossa gama abrangente de moinhos de martelos e como podem otimizar as suas operações de reciclagem de sucata eletrónica. Juntos, vamos abrir caminho para um amanhã mais sustentável.