In today’s rapidly evolving technological landscape, the proliferation of electronic devices has led to a corresponding surge in electronic waste, 또는 전자폐기물. With an estimated 53.6 million metric tons of electronic waste generated globally in 2019 alone, the need for effective recycling solutions has never been more critical. Central to the e-scrap recycling process is size reduction, a fundamental step that prepares electronic waste for downstream processing. In this article, we delve into the significance of size reduction for e-scrap recycling and explore the role of hammer mills in achieving optimal efficiency.

Understanding the Importance of Size Reduction

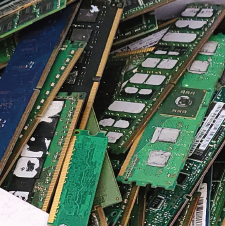

E-scrap, comprising obsolete electronics ranging from smartphones to computers, contains valuable materials such as precious metals, 플라스틱, and rare earth elements. 그러나, the efficient recovery of these resources is contingent upon effectively breaking down e-scrap into smaller, manageable pieces. Size reduction plays a pivotal role in enhancing the accessibility of these materials for subsequent separation and recovery processes.

Challenges in E-Scrap Size Reduction

E-scrap presents unique challenges in size reduction due to its diverse composition, which includes a mix of metals, 플라스틱, 유리, and other materials. Moreover, electronic devices come in various shapes and sizes, necessitating flexible and robust size reduction solutions capable of handling different types of e-scrap efficiently. Achieving the desired particle size distribution while minimizing energy consumption and equipment wear poses additional challenges in the e-scrap recycling process.

The Role of Hammer Mills in E-Scrap Recycling

Hammer mills have emerged as indispensable tools in e-scrap recycling, offering versatile and efficient size reduction capabilities. These machines utilize high-speed rotating hammers to pulverize materials, effectively reducing them to the desired particle size range. Hammer mills excel in processing a wide range of e-scrap materials, including circuit boards, 하드 드라이브, and electronic components, thanks to their adjustable settings and rugged construction.

Advantages of Hammer Mills for E-Scrap Recycling

1. Versatility: Hammer mills can accommodate various types of e-scrap materials, 운영자가 다양한 원료를 손쉽게 처리할 수 있도록 지원.

2. 고효율: 해머의 고속 충격으로 신속하고 효과적인 분쇄가 가능, 처리 시간을 최소화하면서 처리량을 극대화.

3. 맞춤 설정 가능: 해머밀은 입자 크기 분포를 특정 요구 사항에 맞게 조정할 수 있는 설정을 제공, 자원 회수 및 후속 처리 효율 최적화.

4. 견고한 구조: 지속적인 운영의 가혹한 조건을 견디도록 설계됨, 해머밀은 견고한 구조와 내구성 있는 부품을 갖춤, 가동 중지 시간과 유지보수 비용 최소화.

결론

크기 감소는 전자 폐기물 재활용의 핵심임, 폐기된 전자제품에서 귀중한 자재 회수를 용이하게 함. 해머밀은 이 과정에서 없어서는 안 될 도구로 두드러짐, 비교할 수 없는 다재다능함을 제공, 효율성, 신뢰성. As the demand for sustainable recycling solutions continues to grow, the role of hammer mills in e-scrap processing remains integral, driving innovation and maximizing resource recovery in the quest for a greener, more sustainable future.

At Schutte Hammermill, 우리는 전자 폐기물 재활용의 독특한 과제에 맞춘 최첨단 크기 축소 솔루션을 제공하는 데 전념하고 있습니다. 오늘 저희에게 연락하여 해머 밀의 종합적인 제품군과 이를 통해 전자 폐기물 재활용 운영을 최적화할 수 있는 방법에 대해 더 알아보세요. 함께, 더 지속 가능한 내일을 위해 길을 열어갑시다.