Hammer mills are indispensable in many industries, making their replacement parts valuable to have available when you find these machines in need of repair.

Hammer mills are indispensable in many industries, making their replacement parts valuable to have available when you find these machines in need of repair.

În orice mediu industrial, maximizarea eficienței este piatra de temelie a profitabilității și succesului. Pentru companiile care se bazează pe mori cu ciocan și alte echipamente de reducere a dimensiunii, unul dintre factorii cheie care pot afecta eficiența este starea pieselor uzate. La Schutte Hammermill, we understand how critical replacement wear parts are to maintaining peak performance… Citește mai mult »

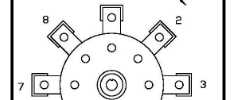

The standard hammers used in our mills are double end reversible types, which have four wearing edges. When hammers become dull to the point where the machine is not grinding efficiently or when the hammers are well rounded, turn the hammers so a new sharp edge will be in service. One row of hammers should… Citește mai mult »

PART ACTION FREQUENCY Bolts Inspect Tighten Daily Guards Inspect Daily Belts Inspect Daily Magnets Inspect Daily Hammers Inspect Weekly Rotate The striking edge is worn. Replace All 4 edges worn. Screen or Inspect Weekly Grate Replace Excessive wear Bearings Inspect Weekly Refill As needed Hammer Rods Inspect Each time you rotate hammers Replace – When… Citește mai mult »

Machines that reduce the size of a material also erode the grinding elements. In general, the more abrasive the material you grind, the more quickly the internal parts wear. To ensure efficient operation and longevity of your Hammer mill, it’s crucial to regularly inspect and replace its wear parts. These components include hammers, rods, ecrane,… Citește mai mult »