Hamermolens zijn onmisbaar in veel industrieën, waardoor hun reserveonderdelen waardevol zijn om beschikbaar te hebben wanneer deze machines reparatie nodig hebben.

Hamermolens zijn onmisbaar in veel industrieën, waardoor hun reserveonderdelen waardevol zijn om beschikbaar te hebben wanneer deze machines reparatie nodig hebben.

In elke industriële omgeving, het maximaliseren van efficiëntie is de hoeksteen van winstgevendheid en succes. Voor bedrijven die afhankelijk zijn van hamermolens en andere verkleiningsapparatuur, is een van de belangrijkste factoren die de efficiëntie kan beïnvloeden de staat van slijtdelen. Bij Schutte Hammermill, We begrijpen hoe cruciaal vervangende slijtdelen zijn voor het handhaven van optimale prestaties… Lees meer »

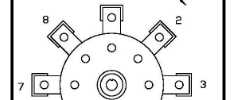

De standaardhamers die in onze molens worden gebruikt zijn dubbelzijdige omkeerbare typen, die vier slijtranden hebben. Wanneer hamers zo bot worden dat de machine niet efficiënt maalt of wanneer de hamers goed afgerond zijn, Draai de hamers zodat een nieuw scherp rand in gebruik komt. Eén rij hamers moet… Lees meer »

ONDERDEEL ACTIE FREQUENTIE Bouten Inspecteren Aandraaien Dagelijks Beschermkappen Inspecteren Dagelijks V-snaren Inspecteren Dagelijks Magneten Inspecteren Dagelijks Hamers Inspecteren Wekelijks Draaien Het slagvlak is versleten. Vervang Alle 4 randen versleten. Zeef of Inspecteren Wekelijks Rooster Vervangen Bij overmatige slijtage Lagere Inspecteren Wekelijks Bijvullen Indien nodig Hamerstangen Inspecteren Elke keer dat je de hamers draait Vervangen – Wanneer… Lees meer »

Machines that reduce the size of a material also erode the grinding elements. In general, the more abrasive the material you grind, the more quickly the internal parts wear. To ensure efficient operation and longevity of your Hammer mill, it’s crucial to regularly inspect and replace its wear parts. These components include hammers, rods, schermen,… Lees meer »