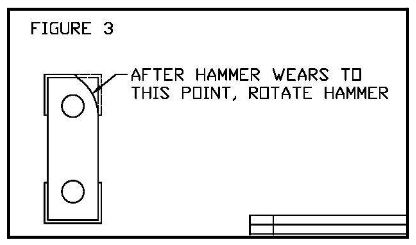

Los martillos estándar utilizados en nuestros molinos son tipos reversibles de doble extremo, que tienen cuatro bordes de desgaste. Cuando los martillos se embotanen hasta el punto de que la máquina no muela de manera eficiente o cuando los martillos estén bien redondeados, gire los martillos para que un nuevo borde afilado esté en servicio. Se debe girar una fila de martillos a la vez para que no se cambie el equilibrio del rotor. No permitas que los martillos se desgasten demasiado o perderás los dos filos opuestos. Los martillos pueden cambiarse por la puerta de acceso del molino con las varillas del martillo deslizándose por las puertas de acceso en los laterales de la parte superior del molino, o por la puerta de acceso principal.

Los martillos instalados en tu molino de martillos Schutte estaban cuidadosamente equilibrados en la fábrica. Los nuevos juegos de martillos de repuesto enviados desde nuestra fábrica también están cuidadosamente equilibrados y cableados en filas. Siempre trabaje en una fila de martillos a la vez y no intercambie martillos de una fila a otra. El manejo descuidado de los martillos puede causar vibraciones excesivas.

Instrucciones de instalación: Equilibrio mediante el método del reloj

Nota: Al llegar,, observe que cada fila o conjunto de martillos está numerado en el martillo superior. Están numerados 1-8.

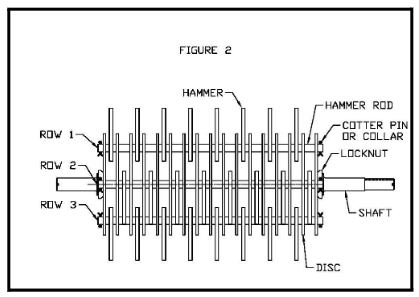

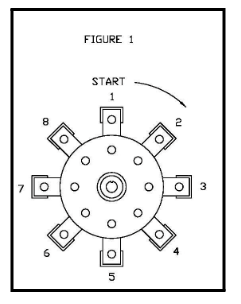

- Comience con la fila marcada como '1'. Como se ilustra en la Figura #1, inserte un martillo entre cada disco alterno. (En algunos casos, dos martillos se colocarán entre cada disco, dependiendo del estilo del rotor).

- La fila 2 seguirá con los martillos colocados de manera escalonada entre los discos, opuestos a la fila anterior. (Ver Figura #2)

- Sigue instalando los martillos de esta manera trabajando alrededor del rotor en orden numérico. (Ver Figura #1)

- Cada martillo tiene cuatro (4) bordes de desgaste. Los martillos deben girarse cuando el filo de rectificado se desgasta aproximadamente a mitad del camino entre el agujero y la esquina original. No permita que los martillos se desgasten más allá de este punto o perderá la capacidad de utilizar los cuatro bordes. (Ver Figura #3)

- Se recomienda reemplazar las varillas del martillo cuando muestren signos de desgaste (como regla general, reemplace el juego de varillas después de usar los cuatro bordes del martillo). Al girar los martillos, verifique si hay desgaste prematuro en la propia varilla. Un surco excesivo en la varilla indicará la necesidad de reemplazo.

- Instale collares o pasadores en el extremo de cada varilla después de girar o reemplazar el martillo.