As the world continues to focus on sustainability and resource conservation, the challenge of managing waste glass has gained significant attention. With billions of glass bottles, Container, and products discarded every year, and uses for milled glass cullet abound, the need for effective recycling and repurposing methods has never been greater. Schutte Hammermill offers advanced… Weiter »

Die Bedeutung von Ersatzverschleißteilen für einen effizienten Betrieb von Geräten

In jeder industriellen Umgebung, ist die Maximierung der Effizienz das Fundament für Rentabilität und Erfolg. Für Unternehmen, die auf Hammermühlen und andere Zerkleinerungsanlagen angewiesen sind, ist einer der Schlüsselfaktoren, der die Effizienz beeinflussen kann, der Zustand der Verschleißteile. Bei Schutte Hammermill, we understand how critical replacement wear parts are to maintaining peak performance… Weiter »

Effizientes Holzabfallmanagement mit Schutte Hammermill

Wood waste is an inevitable byproduct of various industries, including construction, shipping, and sawmilling. Traditionally seen as a disposal challenge, wood waste is increasingly being recognized as a valuable resource that can be repurposed into a range of useful products. Efficient wood waste management is key to this transformation, and Schutte Hammermill offers powerful solutions… Weiter »

Urban Mining: Die Zukunft der nachhaltigen Rohstoffrückgewinnung

Da die Welt mit schrumpfenden natürlichen Ressourcen und zunehmendem Elektroschrott konfrontiert ist, hat sich Urban Mining als eine wichtige und nachhaltige Lösung für die Rückgewinnung von Ressourcen herausgebildet. Urban Mining bezieht sich auf den Prozess der Rückgewinnung wertvoller Metalle und Materialien aus Elektroschrott (E-Abfall) und anderen weggeworfenen städtischen Ressourcen. Mit der wachsenden Nachfrage nach Edelmetallen wie Gold, Silber,… Weiter »

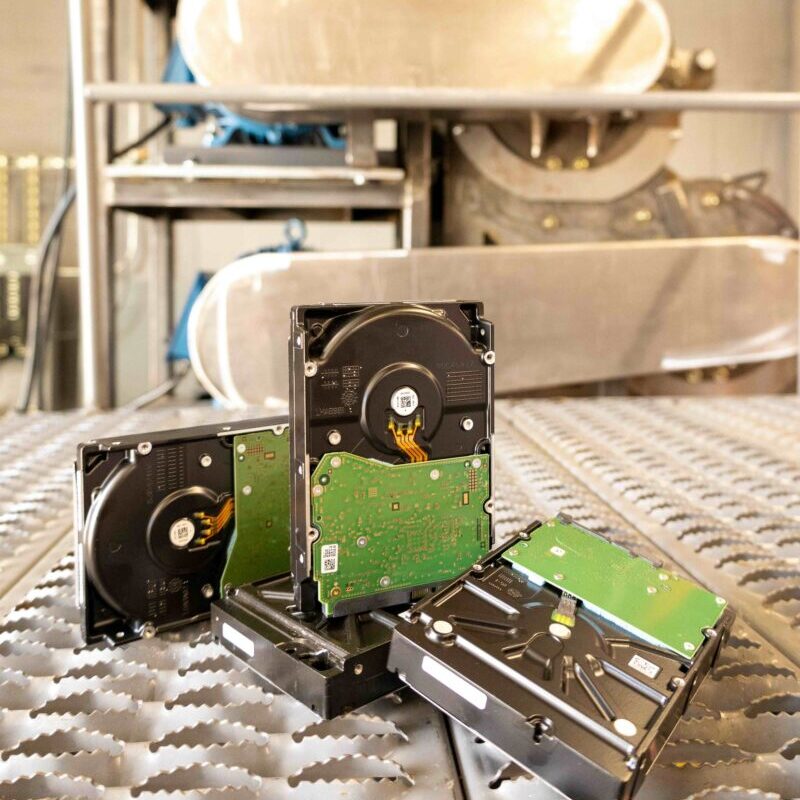

Maximierung der Datensicherheit mit Schutte Hammermill’s DataKiller Pro

Im digitalen Zeitalter, ist Datensicherheit für Unternehmen, Regierungen, und Einzelpersonen gleichermaßen zu einer vorrangigen Sorge geworden. Da Cyber-Bedrohungen sich ständig weiterentwickeln, ist der Bedarf an robusten Methoden zur Datenvernichtung wichtiger denn je. Der DataKiller Pro von Schutte Hammermill sticht als führende Lösung hervor, offering unparalleled data destruction capabilities that ensure your sensitive information is… Weiter »