Chemicals and Bulk Solids

Whether the goal is flowability, dissolvability, or volume reduction, Schutte Hammermill offers the ideal solution for reducing your blocky, abrasive, or hard to process materials to the exact desired finished particle size.

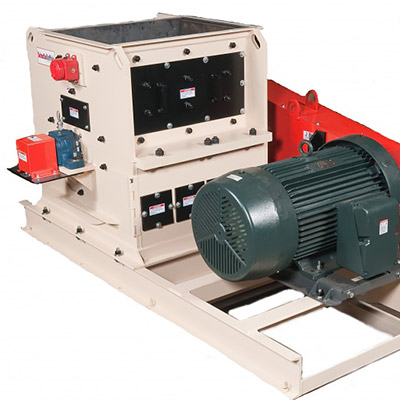

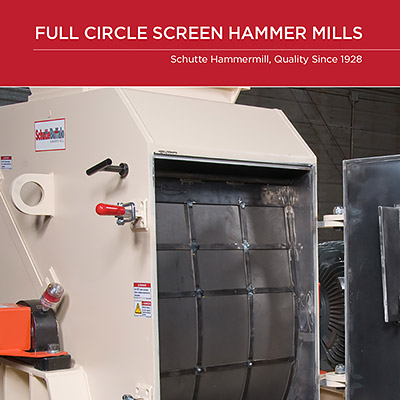

Our extensive line of hammer mills, lump breakers and crushers provide solutions for your chemical and bulk solid processing needs, and are available in custom and standard sizes. All of our equipment is ruggedly constructed to stand the test of time, is available in carbon or stainless steel construction and is custom configured to suit your application and production goals.

Please select your application category below for more information and an introduction to which Schutte Hammermill equipment may fit best.

Advantage

A culmination of decades of industry leadership, innovation, and unwavering commitment to excellence in size reduction equipment. Known for its cutting-edge technology and continuous investment in research and development, Schutte Hammermill sets itself apart by offering versatile and customizable solutions tailored to meet the unique needs of various industries.

Industry Knowledge

A member of the Bengal Machine Family of Brands