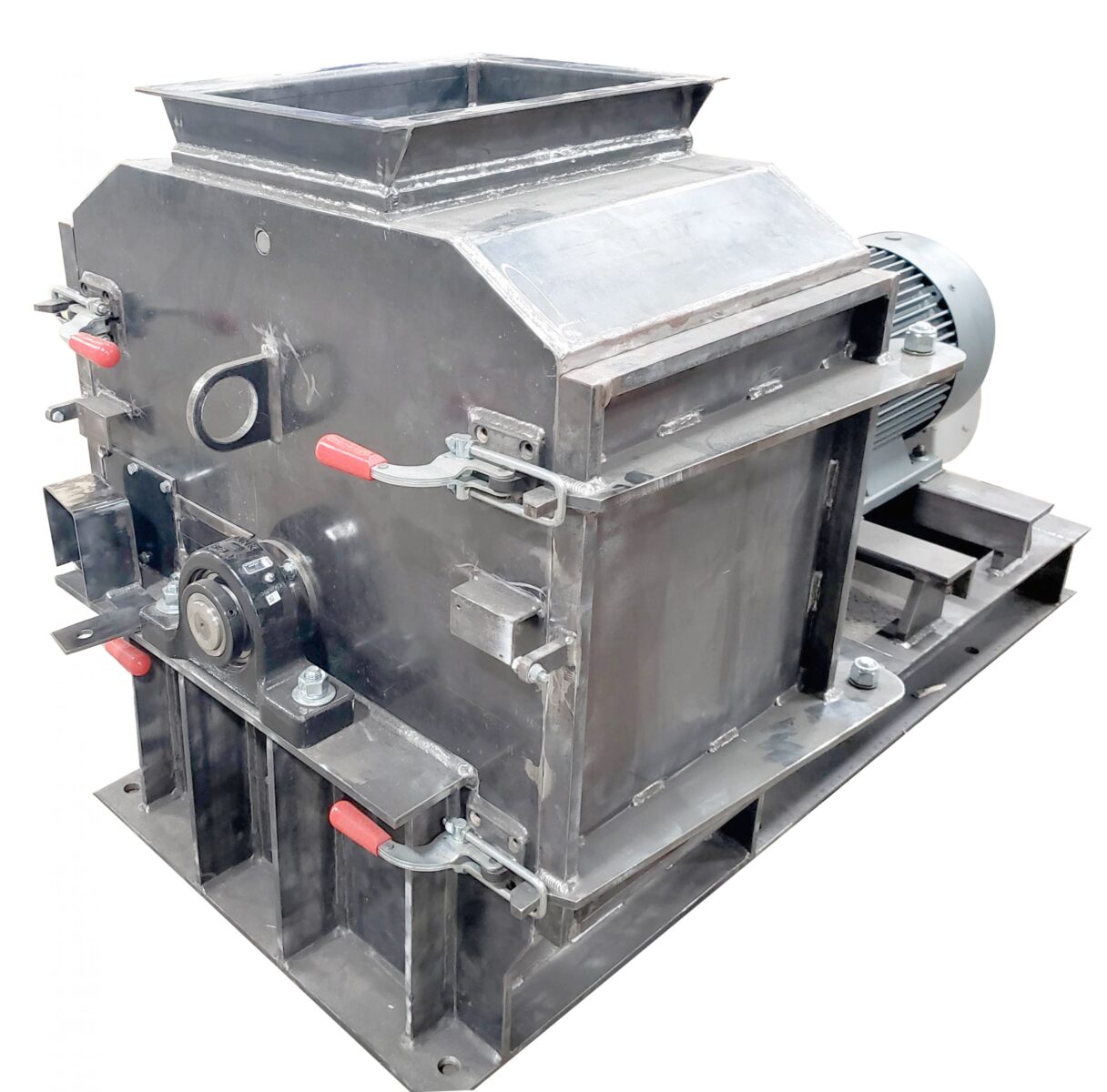

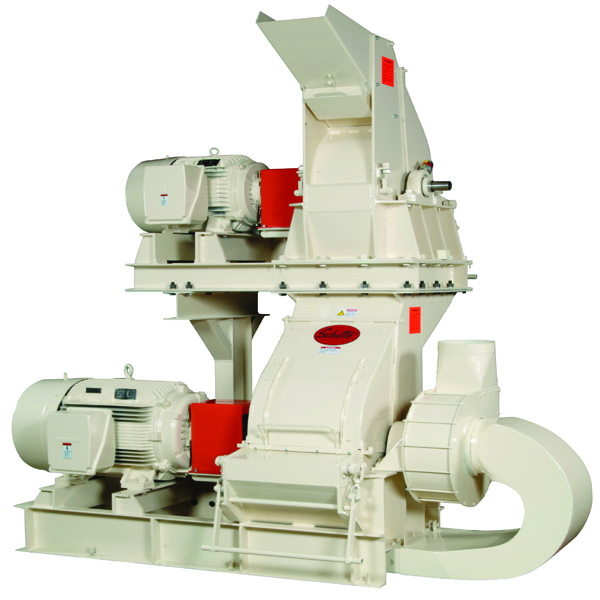

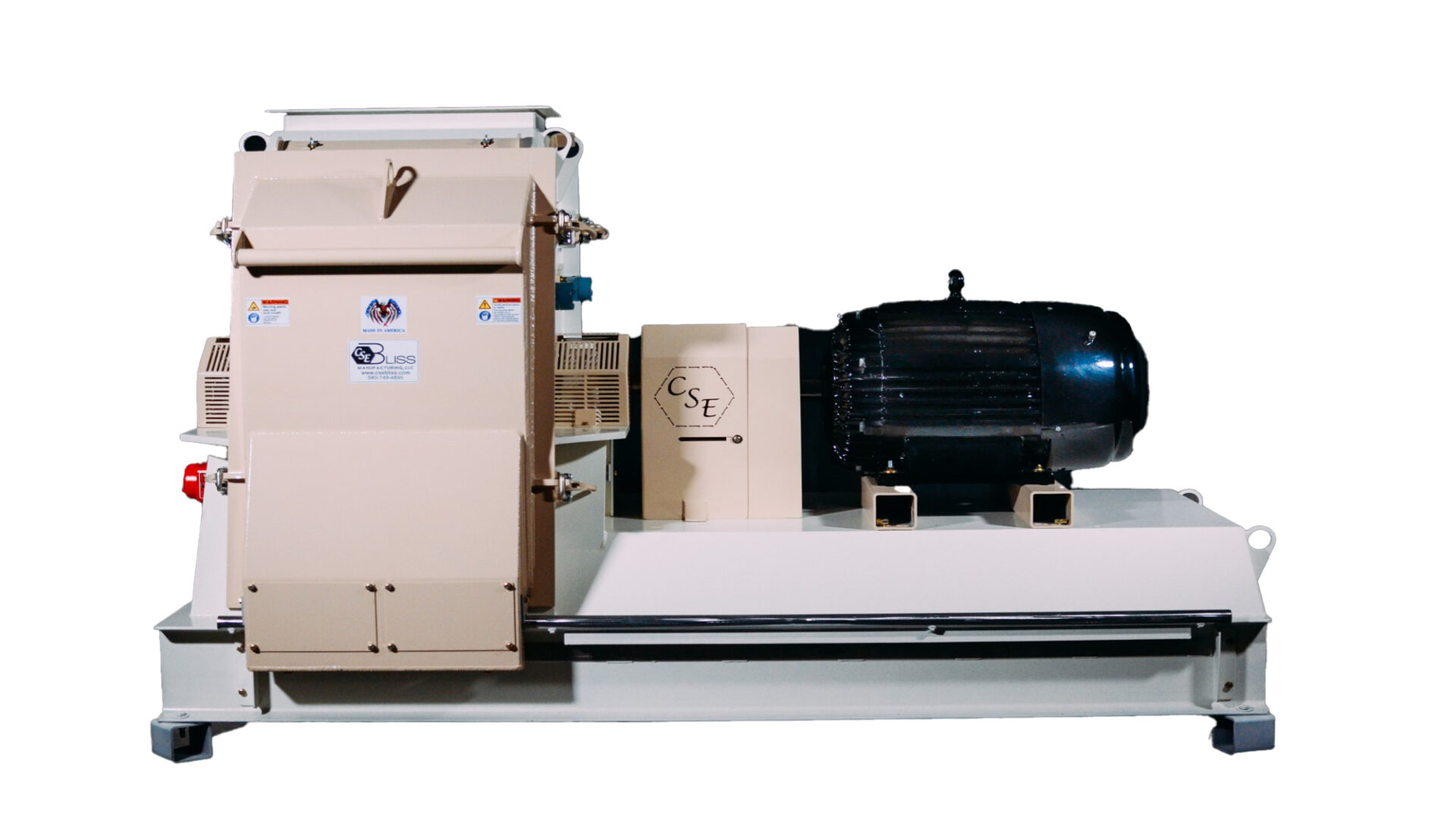

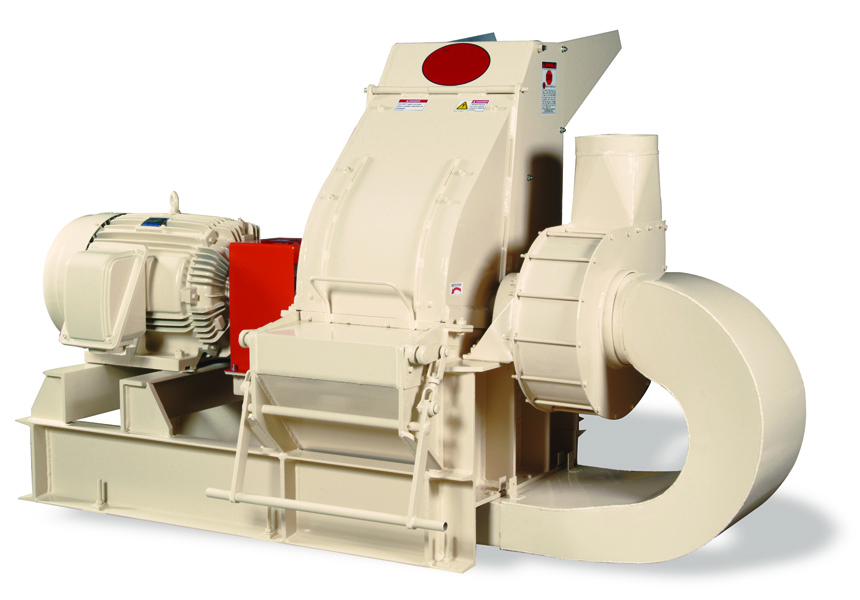

Schutte Hammermill is a pioneering force in providing specialized equipment for processing biofuel feedstock, offering tailored solutions designed to meet the stringent requirements of the bioenergy industry. Our equipment is meticulously crafted to efficiently process various biomass materials, transforming them into high-quality biofuel feedstock. Whether the end goal is the production of pellets, briquettes, or other bioenergy products, Schutte Hammermill's machinery ensures a consistent and controlled output. The equipment excels in size reduction, delivering reliable performance in grinding and shredding processes crucial for biofuel production. From individual units to comprehensive turn-key systems, our customizable solutions empower clients to achieve specific end product requirements and production goals. With an unwavering focus on durability, precision, and efficiency, Schutte Hammermill continues to be a trusted partner in the biofuel industry, delivering innovative equipment that maximizes the potential of bioenergy feedstock.

Equipment for Bio-fuel

Reference Materials

Processed Materials

Wood Chips